Backward integration is a strategy where a company takes control of its suppliers by acquiring or developing them. It’s all about managing the supply chain more directly, giving the business greater control over the materials or services it relies on. This allows companies to reduce costs, improve quality control, and ensure a smoother production process.

Many companies have adopted this approach to strengthen their market position. While it offers many benefits, backward integration isn’t without its challenges. There can be significant financial costs, and it may lead to a more complex operation. Nonetheless, when done correctly, it can set a business apart from its competitors.

Let’s examine backward integration, its benefits, benefits, and risks.

What Is Backward Integration?

At its core, backward integration is when a company merges with or acquires its suppliers. It’s a way to gain more control over the supply chain, reducing the reliance on third parties. This allows the business to streamline operations, lower costs, and improve quality. Think of it as a business getting closer to the source of its materials rather than relying on someone else to provide them.

One key benefit of backward integration is better control over production processes. By owning the supply side, you can ensure consistent quality and cut out the middlemen who add costs. But backward integration isn’t a simple decision. It takes time, money, and resources to integrate new operations, and it can sometimes make a company less flexible in adapting to changes.

While this strategy has helped many businesses become more efficient, it does come with its share of risks. So, companies need to carefully weigh the pros and cons before taking this route.

How Does Backward Integration Differ from Forward Integration?

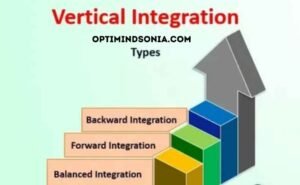

Backward and forward integration are two sides of the same coin, but they focus on different parts of the supply chain. With backward integration, a company takes over its suppliers, moving “upstream” to control the raw materials or components it needs. Forward integration, on the other hand, involves moving “downstream” by taking control of the distribution or retail side of things, like selling directly to consumers or owning stores.

The goals of these strategies are different, too. Backward integration is about securing resources, reducing costs, and improving product quality. Forward integration, by contrast, focuses on getting closer to the customer and ensuring better control over pricing and customer experience. Choosing between these two approaches depends largely on a company’s goals and the challenges it faces in its market. For example, if a company is looking for ways to offer products like a Top-Quality Space Saver Spare Tyre for Hyundai i20 – Compact & Affordable, forward integration could help by improving direct customer interactions.

For example, a business struggling with inconsistent supplies might consider backward integration, while a company looking to build stronger customer relationships might lean towards forward integration. Both strategies can be powerful, but knowing which one aligns with your business’s needs is essential.

Main Advantages of Backward Integration

Backward integration can provide several important benefits for a company, particularly regarding efficiency, cost savings, and overall control of the production process. Let’s break down some of the major advantages:

Cost Reduction

By acquiring or developing your supply chain, you can cut out supplier markups, which immediately lowers production costs. Economies of scale can also kick in, meaning that as you produce more, the per-unit cost decreases.

Supply Chain Control

When you control your supply chain, you’re no longer at the mercy of external suppliers. This means more consistent access to raw materials and fewer delays, ensuring smoother operations.

Competitive Advantage

Backward integration can give you a leg up on competitors. By securing key resources or technologies, you reduce costs and create barriers that make it harder for competitors to replicate your success.

Increased Profit Margins

Cutting out middlemen in your supply chain can lead to bigger profit margins. With fewer hands in the pot, the savings go straight to your bottom line.

Quality Assurance

Having control over your supply means you can almost guarantee consistent quality from the ground up. This can lead to better products and fewer defects, boosting customer satisfaction and brand reputation.

Are There Any Disadvantages of Backward Integration?

While backward integration offers plenty of benefits, it’s not without its challenges. It’s important to consider these potential downsides before jumping into this strategy, as it might not be the right fit for every company.

High Initial Costs

Acquiring or developing your suppliers requires a significant upfront investment. Whether it’s purchasing an existing supplier or building your infrastructure, the financial commitment can be huge. For smaller companies or those with limited capital, this can be a serious barrier to entry.

Increased Complexity

When you integrate more operations into your business, things can get complicated. Managing additional functions, like raw material sourcing or production processes, adds layers to your organizational structure. This can lead to more complicated decision-making and potentially slow down the business.

Reduced Flexibility

By controlling your supply chain, you can sometimes lose the ability to pivot quickly. If a new technology or supplier emerges, it may be harder to adapt because you’ve already invested heavily in your supply processes. This can make your business less nimble in a rapidly changing market.

Potential Inefficiencies

If your company lacks experience in the supplier industry, running those operations may lead to inefficiencies. Just because you’re great at selling a product doesn’t mean you’ll be as effective at producing it. Learning curves and industry-specific challenges can slow down progress and reduce profitability.

Supplier Relationships

Backward integration might strain relationships with other suppliers. Once you become a competitor, some suppliers might no longer want to work with you, limiting your access to innovation or materials you can’t produce yourself.

What Are Some Real-World Examples of Backward Integration?

Several companies have successfully implemented backward integration to strengthen their market positions. These examples can offer some insight into how the strategy can be applied across various industries.

One well-known case is Apple. In recent years, Apple has started designing and producing its chips, most recently the M4 chip, rather than relying on external suppliers. This move has given Apple greater control over its hardware and improved the integration between its software and hardware products, leading to better performance and innovation.

Netflix is another great example. Initially, Netflix relied on external production studios to provide content for its platform. But, with the rise of original content, Netflix started producing its shows and movies. This backward integration gave the company more control over its offerings and reduced reliance on third-party content creators.

Zara has taken backward integration to another level in the fashion industry by controlling much of its supply chain, including fabric manufacturing and design. This has enabled Zara to drastically reduce production times and quickly adapt to new trends, giving them a competitive advantage in the fast fashion market.

These examples show how companies in different industries have used backward integration to improve control, reduce costs, and enhance their products.

What Industries Commonly Use Backward Integration as a Business Strategy?

Backward integration can be particularly beneficial in industries where control over the supply chain is critical to success. While many companies across various sectors use this strategy, certain industries have adopted it more extensively due to their unique challenges.

Automotive Manufacturing

Car manufacturers often integrate backward by acquiring or partnering with parts suppliers. By controlling the production of essential components, automakers like Tesla can ensure the quality of their vehicles while reducing costs and reliance on external suppliers. This also gives them flexibility in developing new technologies, like electric vehicle batteries.

Oil and Gas

In the oil and gas industry, backward integration is common as companies seek to control the extraction and refinement of raw materials. Giants like ExxonMobil and Shell not only sell petroleum products but also own and operate oil refineries, ensuring they have direct access to the critical resources needed to run their business.

Technology

Tech companies are big on backward integration, especially when securing crucial components. For instance, Samsung produces many of the chips and displays that go into its own devices. By owning the supply chain, these companies can innovate faster and keep costs down.

Food Production

In the food industry, backward integration is used to control the sourcing of ingredients. Companies like Nestlé have integrated with suppliers, securing raw materials like milk and cocoa. This control helps them maintain consistency in their products and reduce costs associated with fluctuations in the raw materials market.

While these industries are prime examples, the potential for backward integration can extend across any sector where controlling supply, improving quality, or reducing costs are top priorities.

Final Thoughts

Backward integration is a powerful strategy that can give your company greater control over its supply chain, reduce costs, and improve quality. By acquiring or developing your suppliers, you can cut out middlemen, secure crucial resources, and even create a competitive edge in your industry.

However, this strategy isn’t without risks. High initial costs, increased operational complexity, and potential inefficiencies are all factors to consider. It’s a move that requires careful planning and a solid understanding of your market.

Ultimately, your decision to pursue backward integration depends on your company’s circumstances and long-term goals. For businesses that can manage the challenges, the rewards can be well worth the effort.

FAQs

How can backward integration impact a company’s profitability?

Backward integration can boost profitability by reducing costs related to suppliers and middlemen. By controlling the supply chain, companies can save on markups and improve efficiency, which can lead to higher profit margins.

What are the long-term effects of backward integration on industry dynamics?

Over time, backward integration can shift industry dynamics by creating barriers for competitors. Companies that control critical parts of their supply chain may gain a significant advantage, potentially limiting market entry for others. It can also lead to consolidation within industries, as businesses seek to control more of their value chain.

How does backward integration affect a company’s financial reporting?

Backward integration can change a company’s financial landscape, especially in terms of capital expenditures and operational costs. Acquiring or developing a supplier often requires significant initial investments, which can affect short-term profitability but may lead to long-term gains if executed successfully.

What are the implications of backward integration for market competition?

Backward integration can intensify market competition, as companies that successfully integrate backward can reduce their costs and improve product quality, making it harder for competitors to keep up. Additionally, competitors may lose access to certain resources if a key supplier is acquired.

What economic conditions favor the implementation of backward integration?

Backward integration is often more viable during times of economic stability or when a company has strong financial reserves. Companies with access to cheap capital or that operate in industries where suppliers hold significant pricing power may find it an attractive option.

What are the potential effects on employees during backward integration?

Employees may face changes in their roles, especially if the integration brings in new operations or technologies. There could be a learning curve as the company takes over previously outsourced functions, but in the long run, employees may gain more opportunities for growth and development.